Running a print business keeps getting costlier. So how can you manage rising costs better? Explore our tips for reducing printing costs.

The rising cost of running a print business

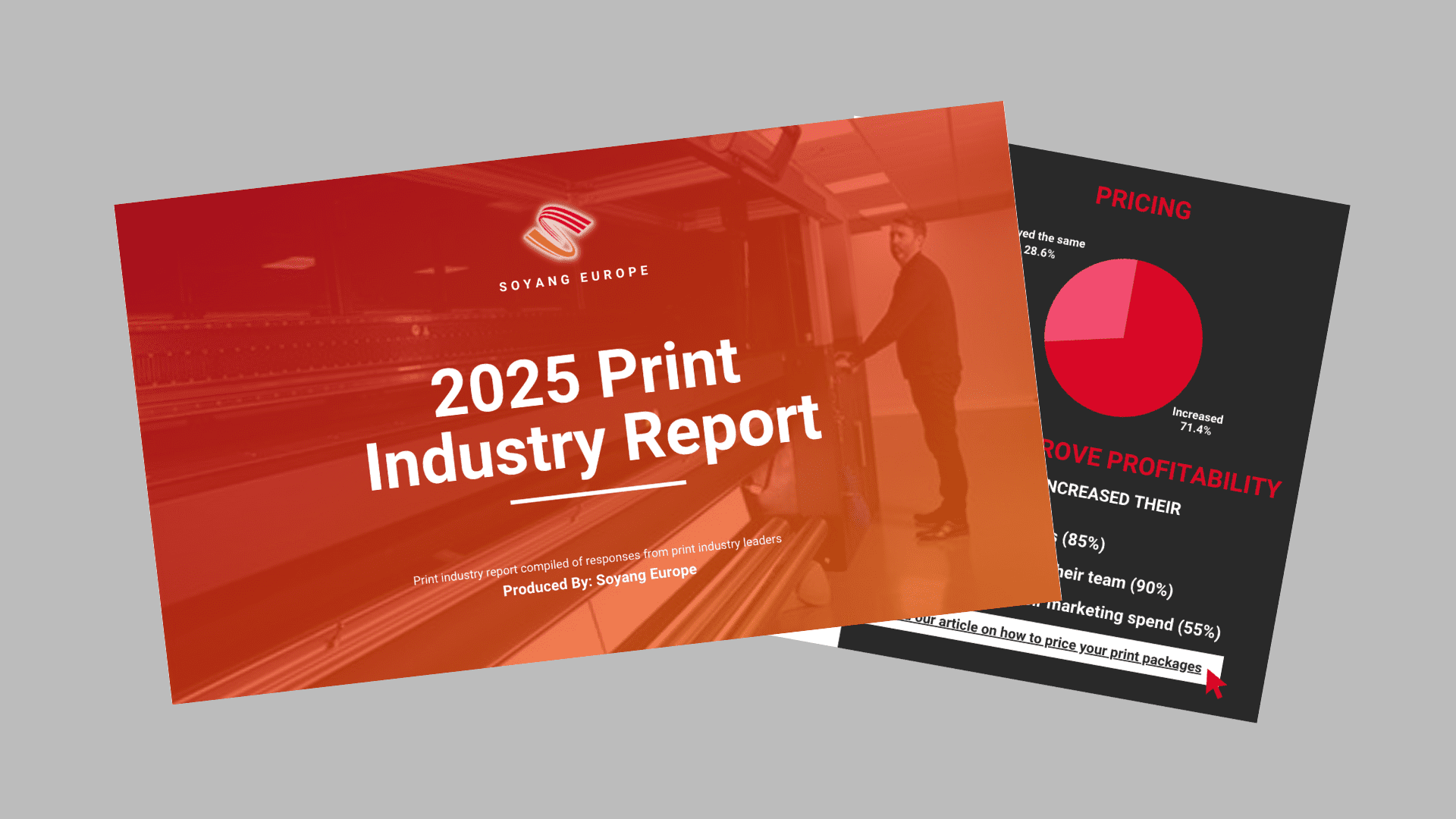

Running your print shop keeps getting more expensive. In our last Print Industry Report, 71% of businesses told us they had increased prices, and there’s only one reason they did that.

The problem, though, is that while print shops increased their prices by no more than 20%, they were subjected to price rises far in excess of that. As we’ll see in a moment, energy price rises alone have dwarfed any increase printers have been able to pass on to their customers.

The only way to square that circle is to manage print costs better – to find new efficiencies and eke out savings that help keep you profitable. In this post, we’ll explore ways to do that.

Reducing printing costs – tips for print businesses

1. Tackle energy costs

Our last Print Industry Report noted that energy prices in the UK rose by 66.7% (electricity) and 129.4% (gas) during the reporting period. Things are more stable now but we’re still living with the legacy of those cost-of-living/Covid/energy crisis price rises of the recent past. To help mitigate those rises, try the following:

- Carry out an energy audit: A good audit can help you understand where to find opportunities for savings, and these could include switching to LED, switching to solar, voltage optimisation and more. Many councils are offering this for free right now as part of supporting more sustainable businesses.

- Schedule high energy processes for off peak: Your print management system should enable you to print projects when you want them. So schedule the most energy intensive ones for off-peak running. Your energy audit (see above) can help you understand the most energy intensive processes,

- Invest in efficiency: There’s only so many tweaks you can make to improve efficiency, especially if you’re operating from an old print shop with aging equipment. Moving premises or investing in new, energy-efficient equipment doesn’t come cheap, but the savings could make it worthwhile.

2. Manage your raw materials

Inventory optimisation is so important here. The ability to run lean but never too lean so you run out of stock. To have a ready supply of the materials you use every day, but be able to source niche materials fast when you need them.

It all matters because the leaner you run the less cash you have tied up in stock. The less risk there is of inventory getting damaged or lost. And the less space you need to store it all.

Invest in a print shop inventory management tool that helps increase the accuracy of your forecasting.

3. Automate to make your people happier (and more profitable)

You’d be surprised just how much potential for automation exists in your print shop that you’re not currently using. And every new piece of equipment brings new opportunities.

Automating repetitive tasks like prepress setup or finishing frees up staff for higher-value work. That means fewer people are stuck doing low value (and low-interest) work and means you can reskill and upskill them so they are able to take on a wider range of duties.

That in turn means there’s less downtime or overtime (because they can perform a wider range of roles) and retaining staff is easier (which cuts the time and cost of recruitment).

4. Buy more efficiently

Consolidate your supply needs – paper, ink, coatings – through a single provider to access better terms and/or economies of scale. The better the long-term relationships you build with your suppliers, the more chance there is of them being able to work with you to help you buy more efficiently too.

5. Target process improvement

Where are the bottlenecks in your processes? Where do tasks get backed up and slowed down? Manage print costs by identifying and improving them, perhaps by consolidating jobs (to reduce set-up times), through investing in equipment that can manage a faster throughput, or through quoting and scheduling tools that streamline your business.

6. Move from volume to value

It can be hard to drive profit from high volume print. There’s always someone who can print more, faster and cheaper. High volume often means real investment in high-throughput equipment. And while automation can keep the per-job cost low, margins are always tight.

As an alternative, consider specialising in the higher value print work that can help build your reputation and protect margins. That might be speciality finishing. It could be high levels of personalisation that enable you to deliver hyper-targeted print campaigns. It might be your use of sustainable materials that sets you apart.

7. Test your changes

As a final business tip for reducing print costs, and whatever changes you make to your print offering or processes, don’t go all-out without testing the changes you’re making. Prove the concept. Start small. Test changes and measure the results so you can see the impact they are having on the way you manage your print costs.

Then, transition gradually so you take your customers with you.

Talk to Soyang

Manage print costs more effectively with Soyang. To explore ways we can help you streamline inventory, manage costs, and shift from volume to speciality, talk to us.