Book a Demo

See the latest print and finishing technology up close and personal. At our Altham demonstration centre, you’ll get hands-on with leading wide-format printers, cutters, and media.

Whether you're exploring new hardware or testing specific materials, our expert team will guide you through a tailored session that’s focused on your business needs.

Enquire about this product

If you want to enquire about this product, please fill in the form and we will get back to you as soon as possible.

Automatic SEG Keder sewing systems that don’t need a sewing specialist Do more with the workforce you already have

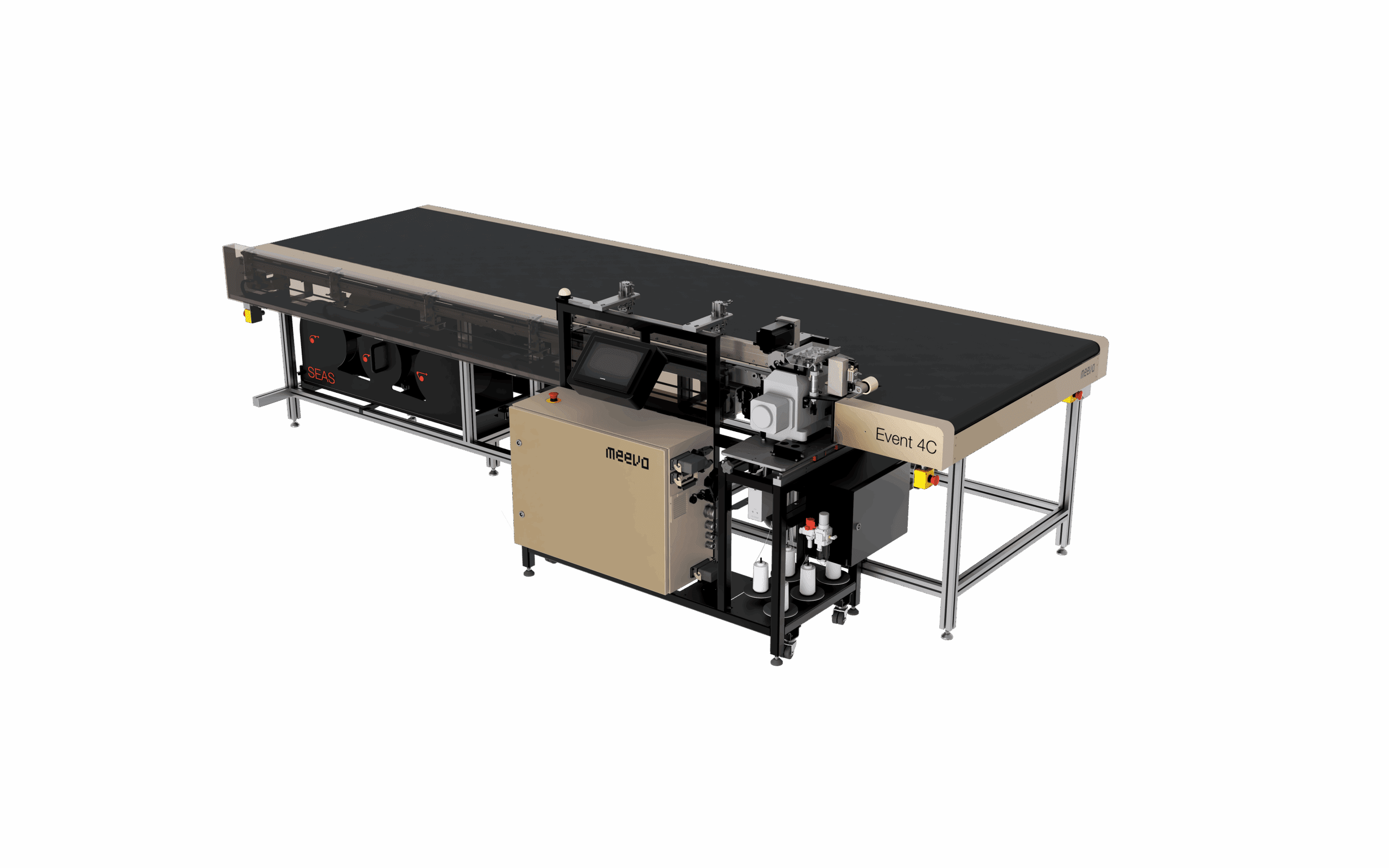

Event SEAS 4C: cost-effective version – ideal for efficient production with essential features.

Take the next step in SEG finishing with our Event SEAS models. Designed to automatically sew flat keder and join large-format panels with precision, these advanced solutions ensure high-quality results and consistent alignment.

With an intuitive interface and full automation, Event SEAS models can be operated by your existing team — no sewing expertise required. A true game-changer, it helps you streamline workflow and meet even the most demanding production deadlines.

Event Models benefits:

• Continuous mode for large production volumes.

• Production cycles with simultaneous loading and sewing.

• Continuous sewing of panels of the same or different formats.

• Control of the machine by movement of the leg, freeing the hands for placement of the panels.

• Full use of the flat keder without any waste.

• Overlock instead of the traditional lockstitch, has significant advantages:

• Reinforced and safer stitching.

• Prevents the fabric from fraying.

• Higher sewing speed.

• Uninterrupted sewing for 10000m of line, compared to 100m of line for other types of sewing.

• Equipped with advanced sensors, the Event SEAS is capable of automatically detecting when there is a shortage of flat keder or thread during the sewing process. If the detectors sense a material supply failure, the machine automatically stops to prevent non-conformities. When the machine stops, the operator can feed again the material for sewing in perfect conditions, ensuring no panel is wasted.