The Lancashire trade-only digital print supplier plans to use the new sewing machine to expand its overall service offering and take on customers in new markets.

Trade-only large- and superwide-format digital print supplier Super-Wide Digital has paid tribute to the impact of its new Meevo MX Event with SEAS from Soyang Hardware, setting out plans to use the sewing machine to take on work in new markets.

Based in the Lancashire town of Bacup near Manchester, Super-Wide Digital offers an extensive range of trade-only print solutions, from banners, textiles and one-piece wallpapers to vinyl graphics and rigid boards. Now in its 25th year, the company has established a network of loyal customers, working with them on a wide variety of applications.

Not one to rest on its laurels, the company is committed to ongoing investment in new technology to support its diverse offering and ensure it delivers a high-quality service to customers across all projects. This approach led the business to invest in the new sewing machine from Soyang, which was installed at its specialist production facility in the summer of 2025.

Supplied in the UK by Soyang Hardware, the Meevo MX Event with SEAS is a silicone edge automated sewing solution that automatically joins large-format panels together with machine-like precision. This delivers high-quality results in large-format display textile applications, allowing users to create a wide range of striking pieces.

While the machine has only been in place for a few months, Super-Wide Digital has already seen a significant improvement in production. Most importantly, as Andy Huskinson, Digital Production Manager and Comms Development explained, the device has sped up the sewing process and helped streamline production for the business.

“Its high-speed motor and automatic thread cutter save time by streamlining the process,” Andy said. “This allows us to produce high-quality work quickly, meeting deadlines and enabling us to produce more output in a shorter timeframe. As one of the early users of silicon edge sewing, we’ve always been heavily involved in silicone edge graphics, but now we feel we can truly push our fabric department to new heights.

“The high-precision stitching, particularly on large fabric panels, results in a more consistent and professional finish compared to manual sewing. The machine’s automation and efficiency significantly reduce the time taken to produce finished fabrics, enabling faster turnarounds and allowing us to handle larger workloads.

“Additionally, the Meevo’s ability to perform multiple sewing operations on a single unit helps us reduce the cost of running various machines, making it a more economical choice than purchasing separate equipment.”

Super-Wide Digital has wasted no time in putting its new device to work, using it to produce a range of impressive applications. Material already being run on the machine includes backlit, blackback and frontlit display fabrics, ranging from very small lightbox panels to fabrics over five metres in size, further demonstrating its flexibility across various projects.

Andy said the company will seek to build on this early success and use the machine to explore new markets and application types as it continues to expand both its service offering and customer base.

“We were impressed by how it gives us a clean and uniform finish when attaching the keder to the fabric’s edge,” Andy said. “We’re looking forward to seeing how it manages with fabric joins, as this is something we have yet to really try.

“At Super-Wide Digital, we are always seeking to invest in new equipment, and we believe that the Meevo will provide us with the confidence to explore new areas, knowing we have a machine we can rely on. “

Latest News

Peerless Plastics & Coatings eyes new customers with Fujifilm Acuity Prime 30 from Soyang

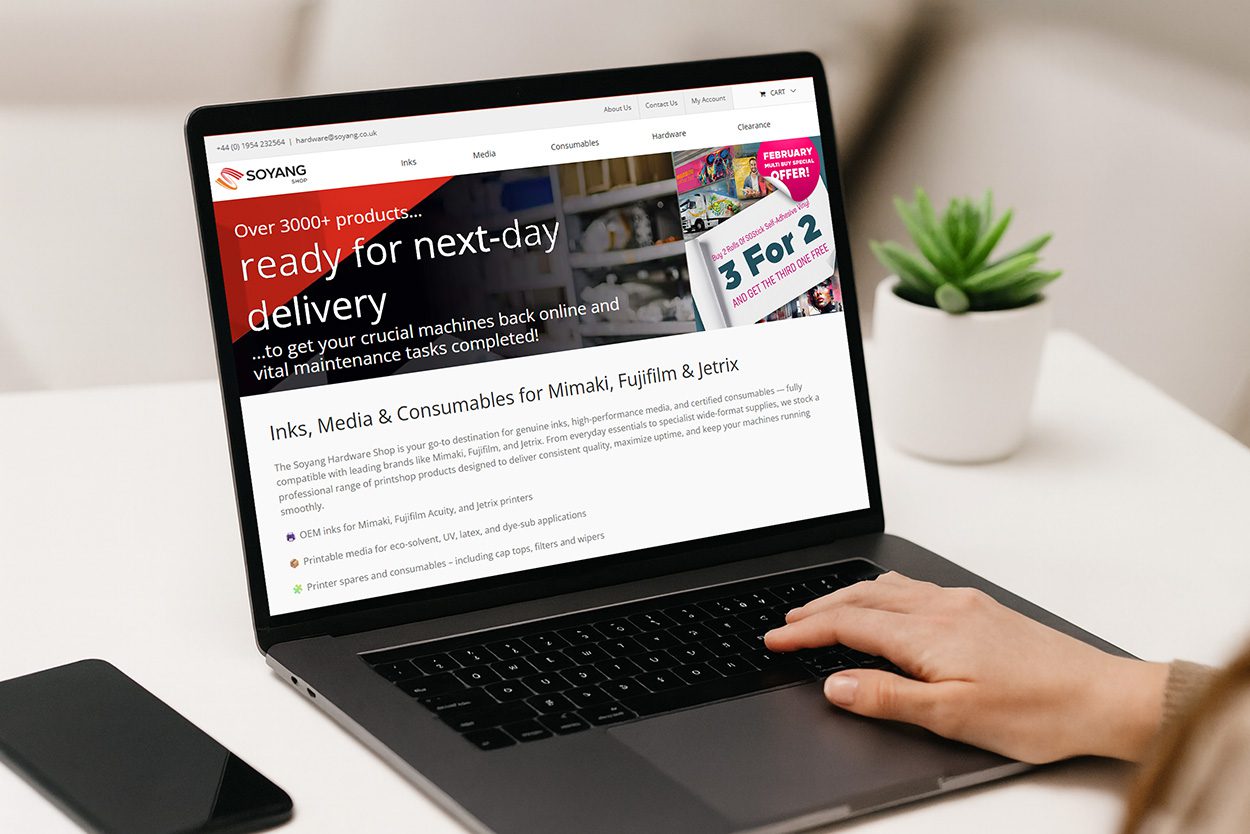

Soyang Europe marks Soyang Shop launch with February promotional offers

Soyang Europe spreads festive cheer with Christmas charity collection drive