Lamination materials go beyond protection – delivering premium print finishing, added durability, and creative effects for signage, graphics, and displays.

Authored by Oliver Mashiter, Sales Director at Soyang Europe.

Traditionally, lamination has been seen as something that printers and sign-makers have had to do to protect printed work. This could be something as simple as ensuring graphics installed outdoors do not get damaged by the weather or protecting floor graphics from the constant flow of footfall that passes over.

However, advancements in recent years mean lamination materials can do this and much more, adding more value to the application. While protection is, of course, often the primary aim, this does not mean that printers and their customers cannot benefit from lamination in other ways.

Picking up on the example of floor graphics again, certain lamination materials carry an anti-slip rating, which means that when applied to printed floor graphics, they will help prevent people from slipping. Certain media have specific slip ratings that perform best in different applications, from indoor exhibition graphics to outdoor event promotion signage. It is vital to take note of these, as incorrect pairing could lead to premature failure or unwanted slipping.

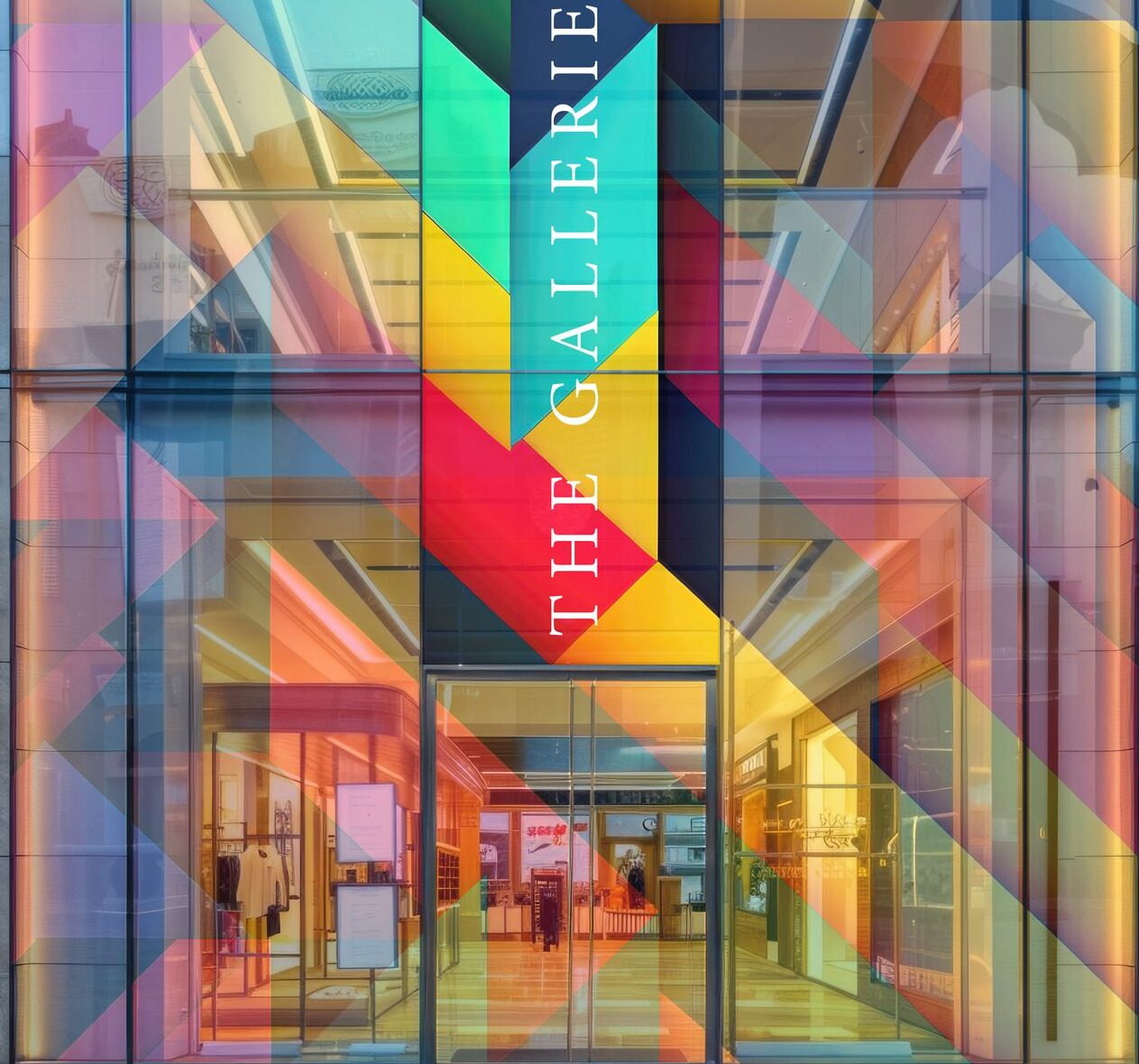

There is also the benefit of textured effects for display purposes. For example, if you want one part of an application to have a different texture than the other – perhaps a pineapple on a supermarket graphic or a basketball on in-store promotional material in a sports shop – then different lamination finishes can help you to achieve a more tactile effect.

In addition, lamination allows print service providers to change the finish of a printed piece. Soyang Europe offers materials that enable customers to achieve finishes such as gloss, matte, sand or satin, allowing customers to add more than just protection, now enabling the printer to give a gloss finish to a matte UV print or a matte finish to a glossy eco-solvent print.

However, with this excitement should come a warning: matching the type of material to the print vinyl is of paramount importance. For example, monomeric print to monomeric laminate and polymeric print to polymeric laminate is best practice as, if they were to do so, they would move and shrink at the same rate and limit the failures to the piece.

Soyang Europe specialises in the supply of printable materials and is well placed to support print and sign companies with their lamination needs. The latest addition to our range is SOStick, a collection of 18 PVC self-adhesive vinyl solutions. All products in the SOStick range are produced in-house at Soyang and are available in monomeric and polymeric films, gloss and matte finishes, offering permanent, removable, grey back, bubble-free, and high-tack options.

SOStick monomeric materials are suitable for use in applications including retail, exhibition, POS, and short-term indoor graphics. Meanwhile, SOStick polymeric solutions can be used to produce various pieces, including signage, vehicle graphics, hoardings, long-term outdoor signage, window graphics, and more.

Vehicle branding and customisation specialist The Vinyl Guys was one of the first businesses to work with SOStick. The Vinyl Guys ran SOStick on eco-solvent and UV printers, producing a set of branded test and inspection stickers for a client in the electrical services market. During the initial run, the company produced hundreds of stickers and reported “genuinely fantastic” prints.

In addition to material, the choice of lamination hardware is also crucial if you are to deliver high-quality work to customers, job after job. Through our sister company Soyang Hardware, we sell lamination equipment from Vivid Laminating Technologies and Mimaki.

These solutions include Vivid’s Easymount Sign laminator, which can laminate substrates up to 50m-long at a speed of 5m/min, allowing users to laminate signs, roll-up banners, window graphics and other applications.

Meanwhile, Mimaki’s LA Series laminators are heat-assisted devices that improve overlaminate film adhesion and reduce the potential for silvering created by pressure sensitive overlaminates.

What was perhaps seen as something of a chore in years gone by can now be used to open up new and exciting opportunities for printers and sign-makers, with lamination allowing them to explore a whole range of added-value effects with their customers.