The Norfolk-based company has been able to speed up production and take on a range of new work from customers across various markets.

Norfolk-based Peerless Plastics & Coatings has praised the impact of its new Fujifilm Acuity Prime L flatbed UV printer from Soyang Hardware, revealing that the machine has allowed the company to speed up production and take on new customers.

Specialising in manufacturing and applying protective hard coatings to plastic substrates, coatings from Peerless enhance durability by offering resistance to chemicals and abrasion, extending the lifespan of plastic products. The company also offers supporting services such as injection moulding, digital printing, screen printing, spray painting, and CNC routing.

Last year, Peerless went in search of a new solution to further strengthen its offering, specifically a printer that could replicate screen printing. This led the company to conduct around six months of testing with the Fujifilm Acuity Prime L, taking delivery of the machine in August 2024.

With a top speed of 204sq m/hr, the machine has a bed size measuring 3,200mm x 2,00mm and six dedicated vacuum zones, allowing users to produce all manner of applications. It also offers white and clear ink options, in addition to a primer ink – the latter of which has been key for Peerless.

Liam Cameron, Head of Print at Pearless Plastic & Coatings, along side their Fujifilm Acuity Prime L

“We wanted to ensure we could achieve a replica product to screen print and verify that their ink was compatible with our coatings,” said Liam Cameron, Head of Print at Peerless. “During this testing, we realised how much technology has advanced over the years. While our older machine still performs well, we were unable to replicate screen printing on it.

“We were seeking an ink that performed well on our substrates. The primer ink included in the machine helped solve this problem and significantly improved our ink adhesion.”

Liam went on to say the impact of the new machine on production at Peerless has been hugely positive. He said the speed of the Fujifilm has increased capacity, thus creating space for new print projects.

“The Fujifilm Acuity Prime L has significantly increased our print room capacity,” Liam said. “For context, the speed of the new printer against the old machine has opened space for new work. We are now able to print obscuration borders for display units, internal glazing screens, and transport-related materials. The increased efficiency allows us to take on a wider range of projects, including more complex custom prints for a variety of industries.”

“We’re confident it will open even more new market opportunities for us.”

Liam also reserved praise for the team at Soyang Hardware and the part they played in helping to match Peerless with its new Fujifilm printer. Nigel Briggs, Business Development manager at Soyang Hardware, worked directly with Liam on the investment.

“Nigel led the project and was always on hand to answer questions,” Liam said. “He was fantastic in turning around the samples we required. We are a little different from other printing companies in that we needed the samples to be compatible with our coatings, and the Fujifilm HF ink performed excellently.

“We were also given the opportunity to visit the Fujifilm ink factory in Broadstairs, where we learned about the R&D side of printing. This experience was invaluable in helping us determine that this was the right machine for our needs.”

Latest News

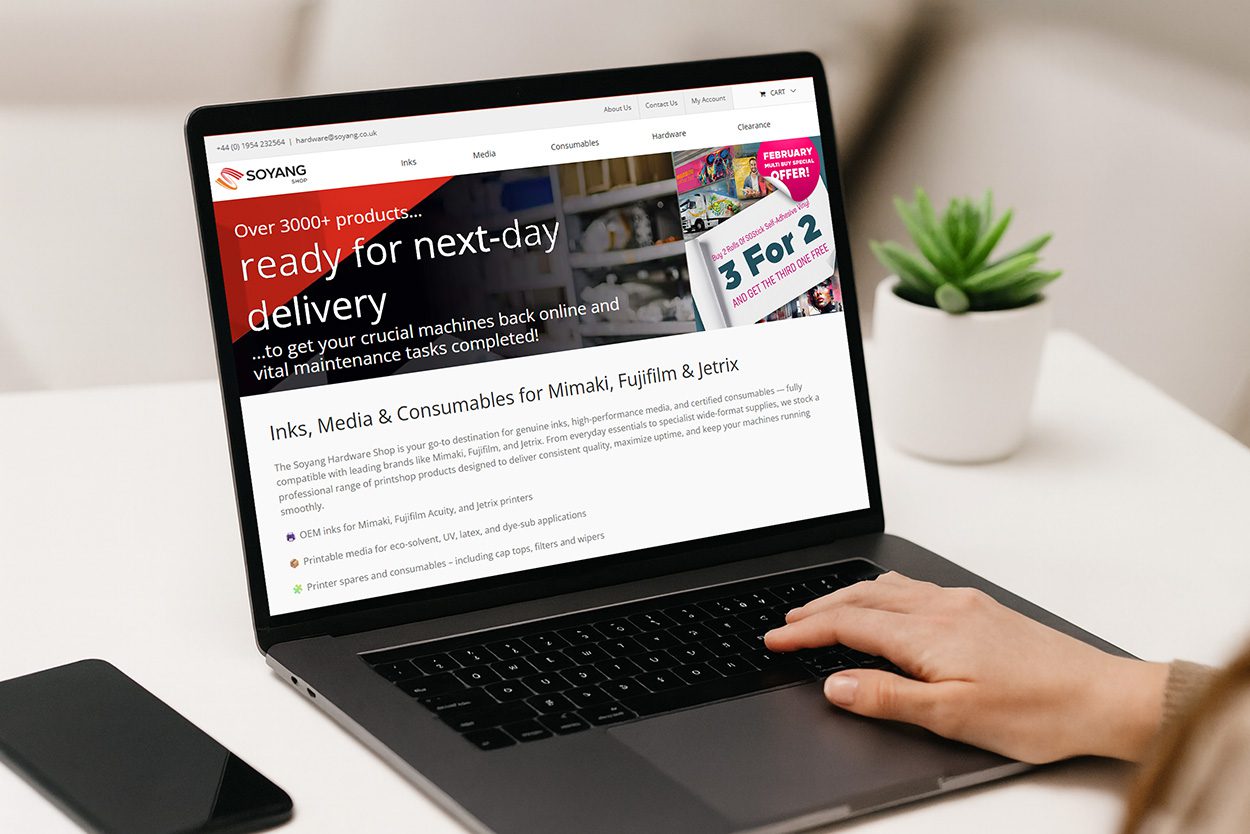

Soyang Europe marks Soyang Shop launch with February promotional offers

Super-Wide Digital maps out expansion plans with Meevo MX Event with SEAS from Soyang

Soyang Europe spreads festive cheer with Christmas charity collection drive