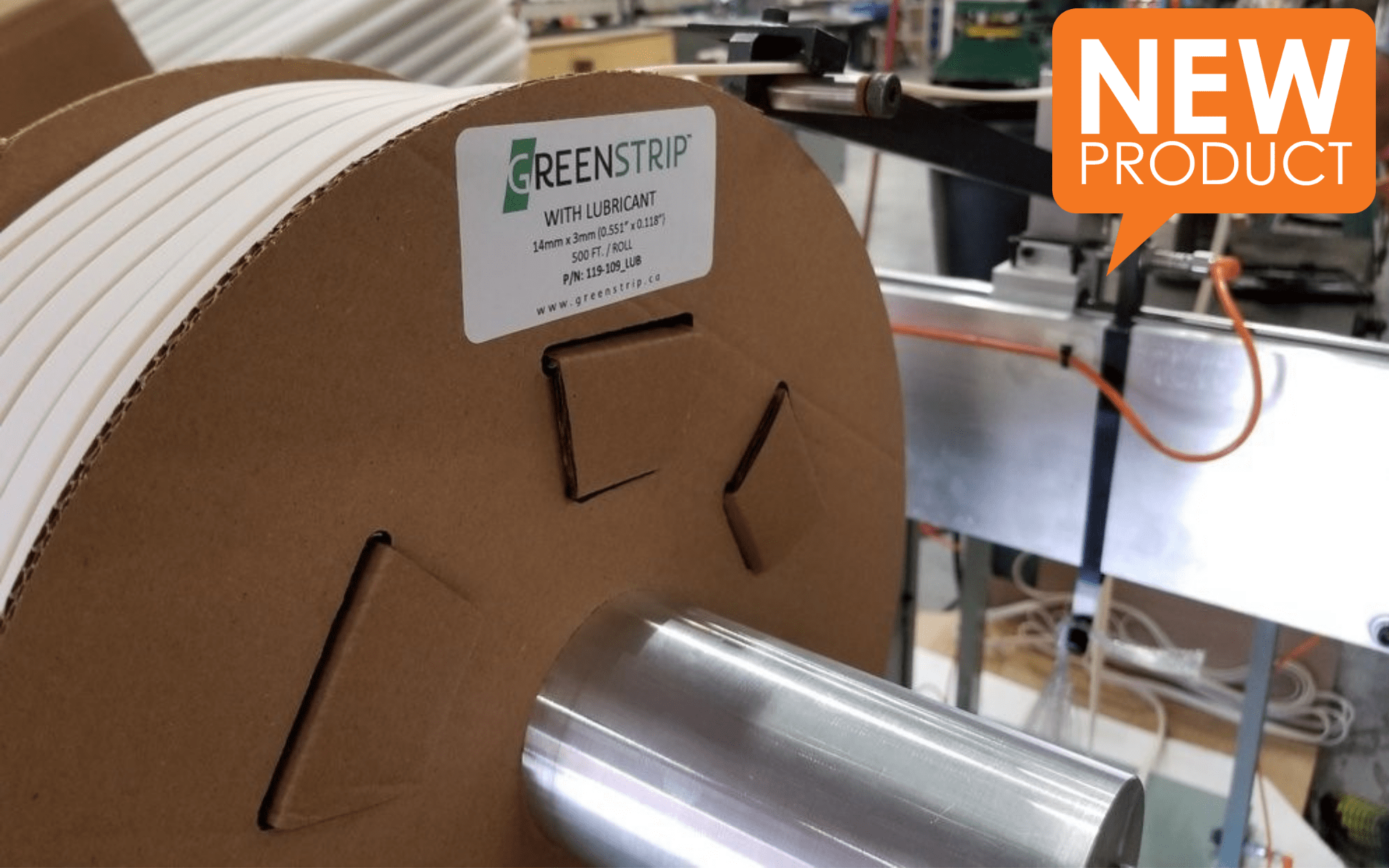

We’ve recently added a great new textile finishing product to the Soyang portfolio: Greenstrip™ Keder. Manufactured in Canada by Evans Engineered Plastics, Greenstrip™ provides a great practical component for many printed textile applications, but also an environmental one, being specially formulated as a PVC-free solution.

We’ve recently added a great new textile finishing product to the Soyang portfolio: Greenstrip™ Keder. Manufactured in Canada by Evans Engineered Plastics, Greenstrip™ provides a great practical component for many printed textile applications, but also an environmental one, being specially formulated as a PVC-free solution.

For those of you already producing printed textiles for lightboxes and framed systems, you’ll be aware of what keder is and its practical benefits for this type of application. For any of our readers yet to explore this area of print application, keder is a flat piece of edging that is stitched into the hem of a piece of printed textile, which then allows it to be locked into a frame or tension system. It helps keep the material in place and ensures the overall look and feel of the finished design is correct.

Evans Engineered Plastics is a specialised plastic extrusion manufacturer focused on delivering engineered solutions to industries across North America. We’re now bringing their expertise to the UK printing industry! Their innovation and determination to manufacture an environmentally friendly keder option is what has created Greenstrip™ Keder.

Greenstrip™ Keder offers all of the mechanical properties required for silicone edge graphics at a lower cost and faster turn-around time than traditional silicone. The Evans lubricant package for GreenStrip has quickly become the product of choice over talc-coated silicone as it is less messy and helps lubricate both sewing machine feed chutes as well as the actual sewing needles.

Greenstrip™ Keder is a thermoplastic, which means there is no curing stage during production; raw materials are simply heated to a specific temperature, pressurized, shaped into the desired keder size, and then cooled before packaging. This allows for high speed production with minimal plant floor space. Evans Engineered Plastics has also designed its own custom packaging equipment to neatly spool Greenstrip™ Keder while keeping it free of dirt and contaminants.

The material used to produce Greenstrip is formulated to be environmentally friendly. In addition to being PVC-free, Greenstrip™ Keder can be recycled in traditional recycling chains that handle polypropylene (PP) based products and can be recycled indefinitely with virtually no reduction in mechanical properties. This gives great green credentials to match the environmental benefits of working with textiles over other substrates.

To find out more about Greenstrip™ Keder or how to get into textile printing, give our team a call on 0161 765 3400.