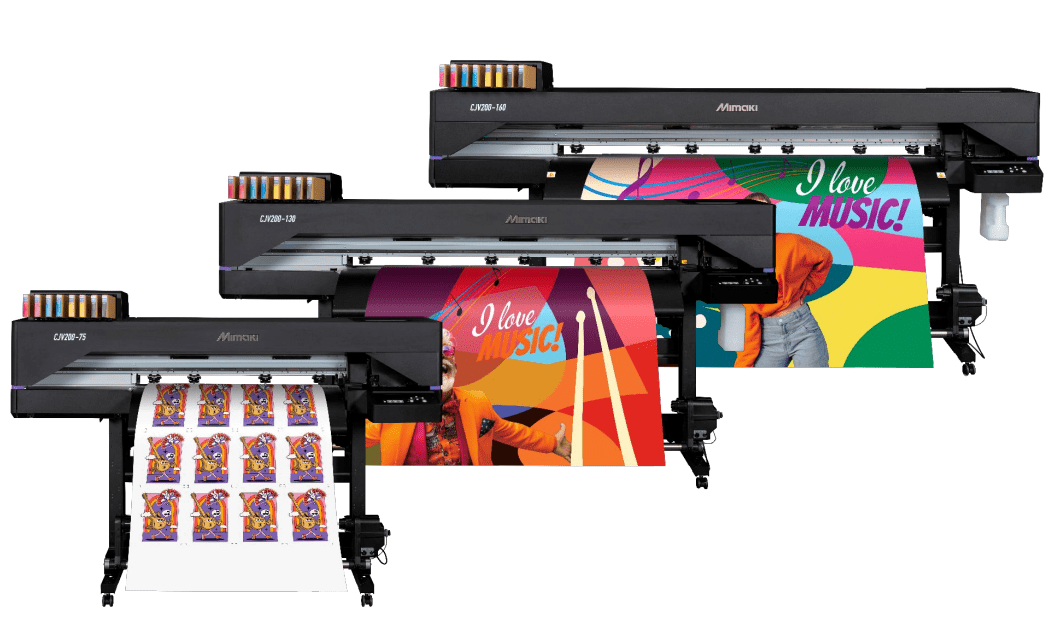

Mimaki CJV200 Series

- Eco Solvent

- Print & Cut

- Speeds up to 70²/hr

- Fantastic Entry Level Printer

- Signs & Graphics, Exhibition & Events

- Banners, Vehicle Graphics and more!

Buy 2 rolls of SOStick Self-Adhesive Vinyl and get the third one FREE!

Soyang Europe Ltd offer a wide range of grand format printable materials, all available via next day delivery from our fully stocked warehouse here in Lancashire. With materials suited to latex, UV, solvent and dye sublimation as well as expert advice from our team, in house sampling and testing there is something for everyone.

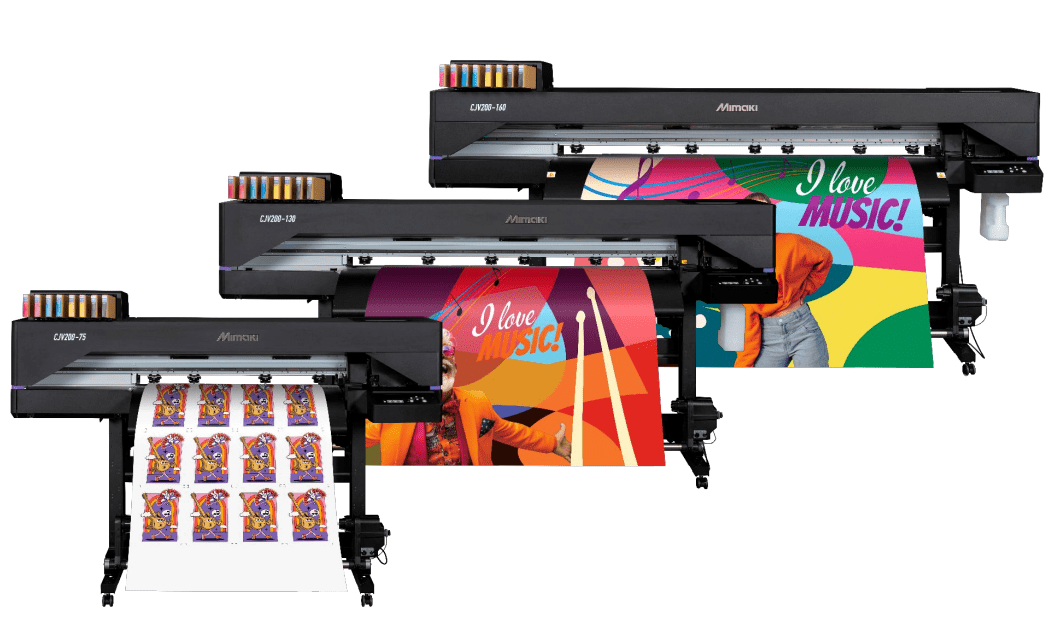

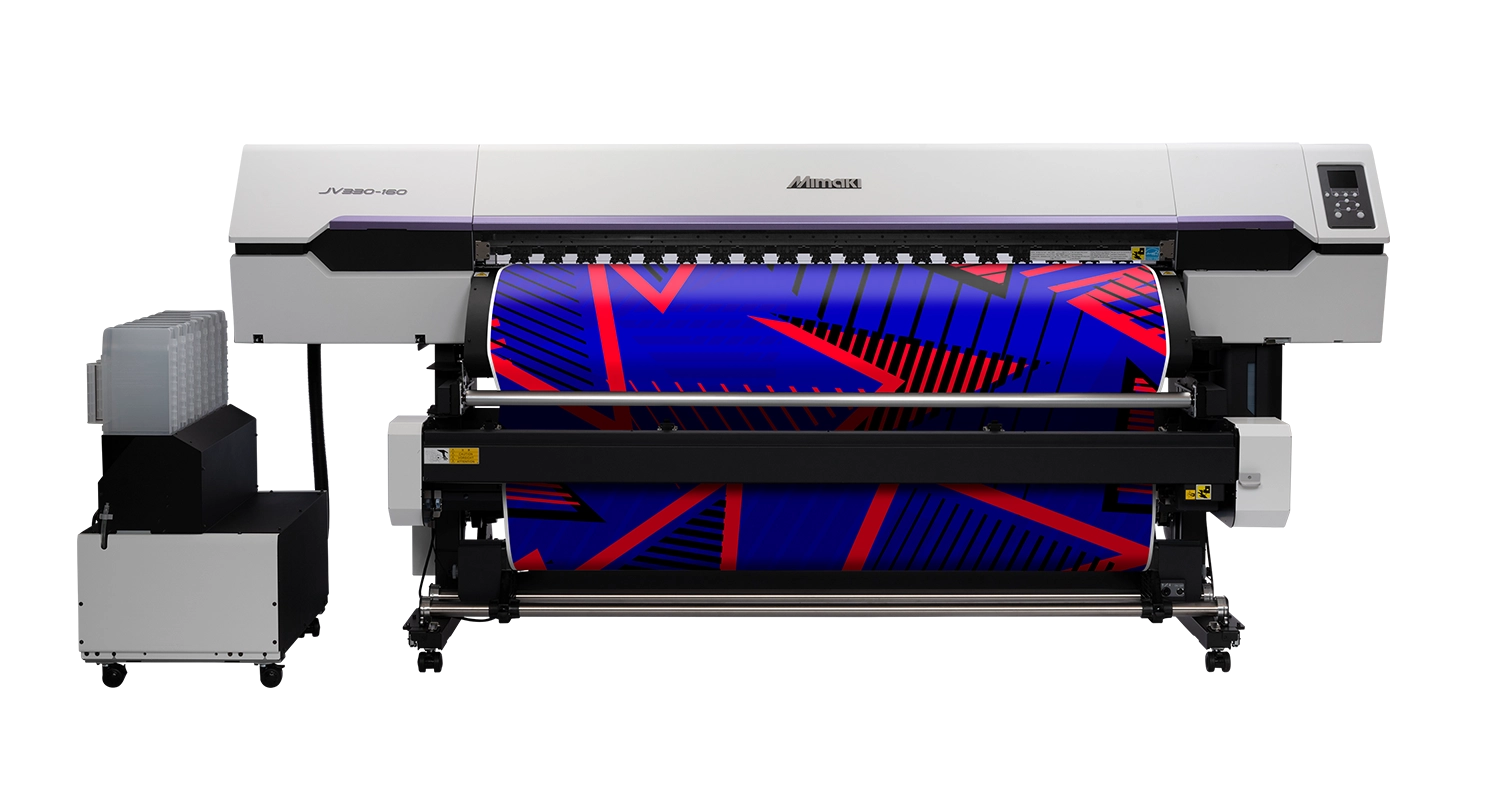

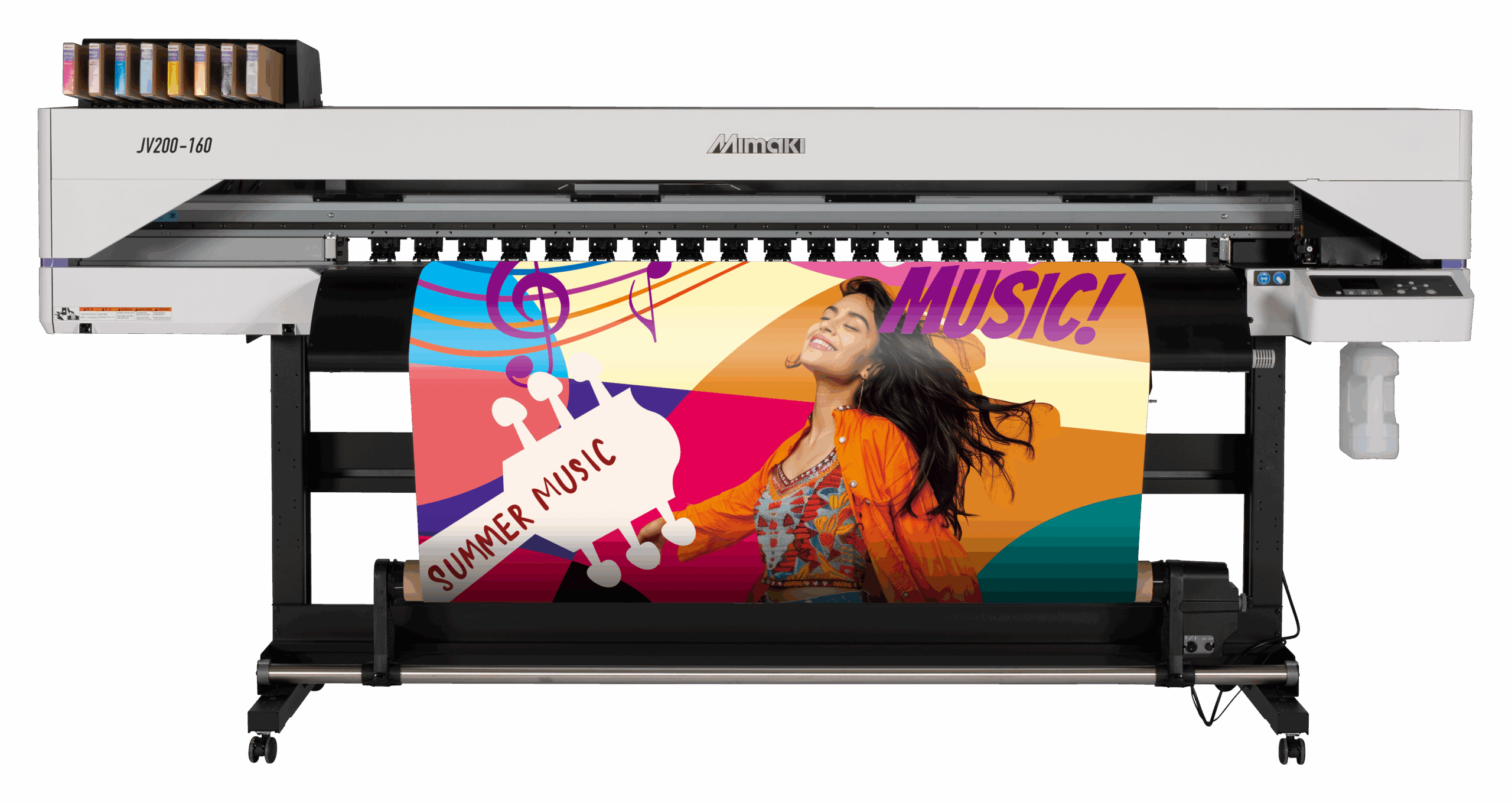

We are proud to supply, install and support hardware from industry-leading manufacturers. We are authorised resellers for major, well-respected brands such as Jetrix, FujiFilm, Mimaki, Meevo, Bubble-free, Vivid and many more.

Our team can advise on our product range, their applications, and how they might suit your project.