Print customers are increasingly requesting and specifying greener materials, helping their supply chains become more sustainable. Large format printing is no exception and the industry has responded by providing machines that use less electricity, processes that use less water, curing that utilises less heating and focussing on developing newer, greener substrates and materials.

When and Where to Consider Eco-Friendly Fabric and Textile Material

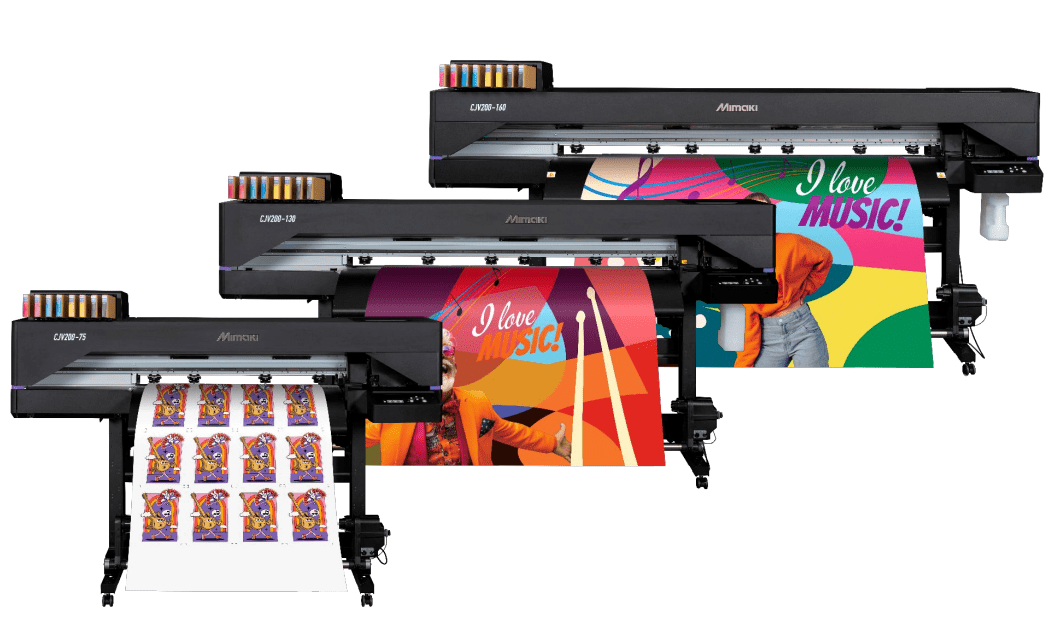

Large format digital printing is widespread and used for showroom and retail displays, exhibition graphics, flags and banners as well as flooring projects. The print quality of the latest range of large format printers can produce remarkable imagery, with clear lines, high resolution and vivid colours.

Yet sustainable textile printing can only exist in tandem with supply chain transparency, and with effective collaboration, the large format fabric sector can make big strides in becoming an eco-friendly solution. Public sector spaces are under ever-increasing pressure to offer a sustainable environment filled with sustainable products. So too are educational, and health facilities. But the biggest market is found in retail where showing off green credentials is demanded by customers.

What Type of Textile Printing is Greenest?

Latex – By far the most eco-friendly printing method is latex. Often fully recyclable, it is a technology that has greatly advanced in the last few years. Latex ink works well with any fabric both synthetic and natural. There is no need for additional waste processes like transfer papers.

UV – Eco printing on fabric using large format UV technology means that the ink is sublimated to the substrate using an inline fuser. It can adhere to almost any surface including a wide range of fabric and textiles, both synthetic and natural.

Dye sublimation – This method remains a popular form of printing because it can reproduce photo-like quality to a wide range of fabrics where the ink is printed onto screen paper before being pressed into the fabric or textile to transfer the image.. From textile flooring to retail exhibition displays, this type of printing absorbs water-based inks ensuring the inks penetrate the fabric weave. However it still produces waste in the form of excess ink and transfer papers.

Reducing Waste in Textile Printing

More than ever the digital printing technology is able to complete on the promise of a greener future and cleaner environment. Print consumers are more conscious of their carbon footprint and are specifying more sustainable products from suppliers. And these processes are being continually developed to improve and replace older, unsustainable manufacturing practices.

For instance using laser cutting technology minimises excess material waste. Using a large format cutter can cut and seal all types of fabric at the same time, reducing the need for overlapped edges and additional machinery for sealing the finished product. It also promotes longer life expectancy for a product where fraying and unstitching are expected tradeoffs for flexibility. Additionally laser cutting ensures accuracy first time, every time.

Furthermore, as we head towards more responsible manufacturing, recycling can offer extended life for textiles fibres. All the choices made in the design process will impact the future life of the large format print and repurposing offcuts can also help improve and fulfil those same recycling initiatives.

It’s also interesting to know that textile manufacturing across multiple industries that used analog technology once consumed immense amounts of resources and generated (now viable) waste. This included water, energy, waste material like inks and dyes and chemical solutions, which are toxic to the environment.

Eco-Friendly Benefits of Latex and UV Printing

In digital printing, the more advanced the technology, the cleaner and greener the process tends to be. And latex, more than any other method, is considered the most sustainable. Closely followed by UV printing which has taken huge technical strides in energy efficiency, and with it a whole new light can be shone on the eco-friendly capabilities of modern fabric and textile printing.

Less waste – When printing directly onto the garment there are no secondary processes required. So while transfer printing uses a substantial amount of ink, much of which will be wasted during transfer, latex and UV only uses the amount of ink required to print.

So, when less equipment is required during the set up of the print process (there are no screens or plates needed to create and transfer designs onto) then no bulky waste products are produced. All of which will eventually need to be disposed of as waste once each print run is completed.

Water conservation – It is well known that a huge amount of water is required to produce fabrics and textiles, but it is also the case that it takes a lot of water to produce printed fabrics too. This is the same with the cleanup process involved in screen printing too.

With more modern machinery and advanced ink sublimation technology, it can save millions of tonnes of water being either wasted or polluted and colour-fast pigments are now used to impregnate the textile fibres. Using heat or UV eliminates the need for either pre-wash treatments or post production processes involving water like steaming or washing.

Energy efficient – Digital submission of large format designs enable prints to be submitted directly to the printer. No transfer papers means less physical waste, only the ink required to print and it is quicker. Add in the adoption of low energy using UV lamps and the process of screen transfer can look positively analog.

Moving Forward with Eco-friendly Textile Printing

Modern improvements to digital printing have allowed eco-friendly textile printing to be done in a manner benefiting the environment. It allows environmentally aware consumers the luxury of choice when it comes to their textile and fabric print needs.

Digital printing technologies are constantly moving forward. In large format fabric/textile printing positive steps are being made to replace traditional, but ultimately unsustainable printing methods. Choosing sustainable textiles is now corporate policy for many retailers and brands both seeking to improve their environmental credentials and impact both locally and globally.