Latex printing is one of the newest ink printing technologies and was developed as an alternative to the chemical-based inks like solvent. Large format latex printing has expanded print technology to produce large and vivid print graphics on all surfaces and in all environments. This guide will help you understand how it works and when and where to use this flexible printing option, as well as some of the benefits and considerations of using the latest latex printing technology.

What is Latex Printing?

When we refer to latex printing, we are talking about synthetic latex. Synthetics work in the same way as the natural resin originally discovered in the milky fluids of certain tree and flowering plant species. This liquid has unique properties that coagulate and solidify on contact with air.

Latex printers use print heads to distribute the ink onto a whole host of varying media. The latex itself becomes the carrier for the colour pigments and heaters dry the ink as it rolls off the printer meaning it can be installed immediately.

Synthetic ink forms a film on its surface, and additional heat sources cure it much quicker than other inks. It is odourless and efficient and doesn’t release any potentially toxic or noxious solvents. But perhaps its most distinguishing feature is flexibility. It can stretch (to a degree) on any material making it a preferred option for many textile and vinyl applications.

Latex is considered a successor to solvent-based printing and has a wide range of applications. It can offer quicker turnaround times and superior quality output. The colors are solid, the consistency outstanding, and latex ink can be printed on an assortment of coated or uncoated substrates and media.

What is Large Format Latex Printing?

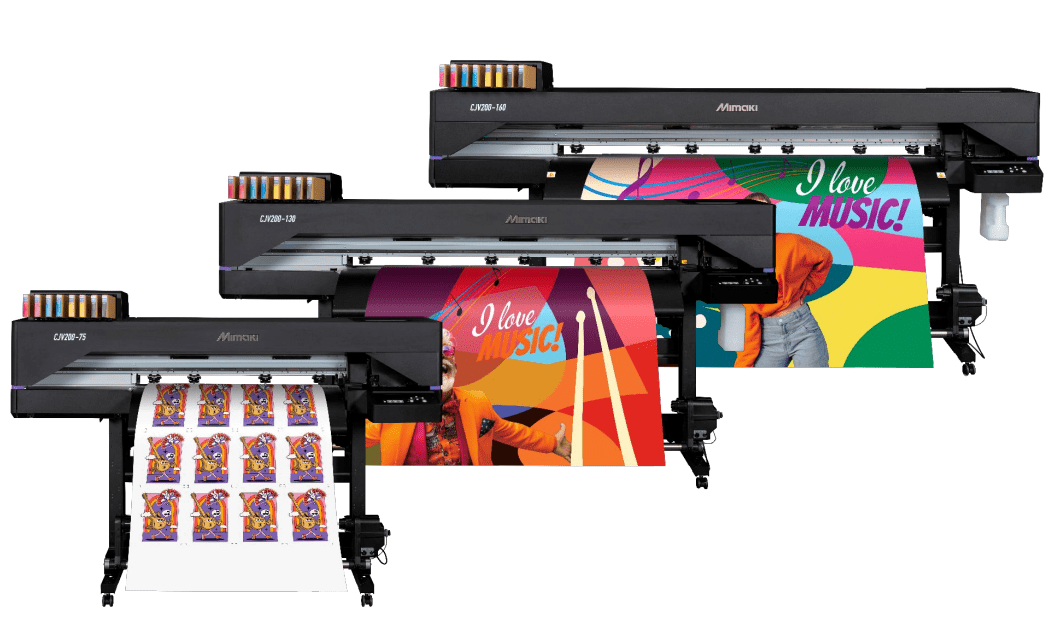

Most latex printers are hybrid printers, so they are able to print on both rigid and flexible media, often upto 5m wide, quickly with a superb range of colours. When volume is critical, latex printing is a go-to option for tight deadlines.

Large format latex printing can be used for a wide variety of projects. It is best suited to flexible mediums, but can also be utilised on a number of versatile formats too:

- Banners

- Backlit Graphics

- Canvas

- Exhibition Signage

- Fabric

- Flags

- Garage Doors

- Murals

- Stickers

- Store Fronts

- Textiles

- Signage

- Vehicle Wraps

- Wallpaper

- Window Graphics

When and Where to Use Large Format Latex Printing

One of the best uses for latex inks is on vinyl. Because self-adhesive vinyl can be a sensitive material it must be handled with care, using latex printing can be less impacting on the media ensuring a superior level of quality control.

Wraps

One of the best uses for latex printing is the utilising its compatibility with self-adhesive vinyl for purposes like vehicle wraps. Latex will only ever soften the surface of the self-adhesive. The alternative when using solvent printing is having to use chemicals to dry and bond, or extreme radiation, as is the case in UV printing. Latex printing allows the vinyl self adhesive surface to be left largely unaffected by the printing process, resulting in long-term adhesion and extended life expectancy.

Textiles

Latex printing and home decor are often talked about in the same breath, and it makes sense to use latex inks on wall coverings and fabrics due to the innate flexibility of latex compounds. This includes using it within fashion (increasingly used on clothing) and for interior design purposes on floors, walls and furniture.

Healthcare and educational environments

As opposed to solvent-based inks (containing compounds that can be harmful to people and the environment), latex ink is made up of 70% water, meaning it is ideal for indoor environments and especially suited to settings where the young and vulnerable are. So latex printing is often the choice for healthcare and educational interior printing.

Over lamination

Lamination is the addition of either a lacquer or a film onto the printed surface to provide additional levels of protection or colour enhancement, or just to prolong the life of the product in external or abrasive environments. One of the best properties of latex printing is the ease of secondary processes like lamination.

- Protects graphics from the effects of pollution in urban or industrial settings

- Adds resistance from abrasion, scratching and mishandling

- Makes cleaning easier, as chemicals do not affect the printed material.

Benefits and Considerations of Latex Printing

Benefits of using latex printing:

- Often when printing on wraps, the stretching process can lighten colours and give them less expressive impact. But using latex colours maintains colour-intensity, lessening any bleaching or diluting effects.

- Because latex ink is water-based, the finished printed product is durable and eco-friendly.

- Latex inks are odourless and immediately ready for internal use

- Latex printing is one of the fastest print technologies with little to no curing time

- Adapted perfectly for over-laminating.

Considerations of latex printing:

- High temperature drying

- Poor scratch resistance (consider over-lamination)

Even though it is one of the newest ink technologies available, all of the limitations such as high-temperature drying and poor scratch-resistance have been overcome, and printers and inks still continue to be improved as demand grows.

Conclusion

Latex printing has come a long way fast. Originally touted as a successor to solvent-based printing it has found its place among UV and Solvent as one of the foremost printing options for large format printing.

Its benefits of being able to produce quick print runs and being chemical-free have promoted it as an environmentally sound choice and as a preferred option for interior settings in the health, education and the restaurant sectors.