Different banner types present many choices – of material, printing method, fixings and more. Here, we explore your banner options.

“We need a banner.” If we had a pound for every time someone had said that to us, frankly, we probably wouldn’t need to be in the business of selling the material for them. But beyond that statement are lots of considerations that will ensure the banner you get is the banner you need.

Where will it be used? Who will be interacting with it? Will it be viewed up close or at distance? Will it be outdoors or in? The answers to such questions will help inform your choice of large format print material (vinyl, mesh, fabric etc), and the application and choice of material will help determine the print method you use to put your image/message on the banner.

Finally, with all the above decided, you’ll want to ensure your banner will stay in place, and that will mean marrying the right fixing with the appropriate choice of finishing or hemming.

Banner options 1: Print materials

Your starting point in assessing your banner options is the material of the banner itself. So will it be vinyl, mesh or fabric?

Vinyl

Not all vinyls are the same. Which you choose is a matter of balancing where your banner will sit, how it will be fixed and what print method you will use on it. A relatively thin ‘scrim banner’ will be low cost because a) it uses less vinyl and b) you can use cheaper print techniques on it. Outdoors, however, that may result in a banner that doesn’t hold up to the elements.

Outdoors, therefore, a thicker banner with a vibrant solvent- or low-solvent-based print, together with a hardwearing coating, will be the costlier but far more durable option.

Mesh banners

There’s a certain banner type that you’ll always see wrapping a construction site, hanging from the football stadium or concert venue or lining the hoardings on the way to the sports arena.

Mesh banners are chosen for these applications because they deliver vibrant print on a large scale, while taking advantage of the mesh construction to withstand stormy conditions. Wind just passes straight through, which reduces stress forces on the banner and the structure to which it is anchored.

Always consider adding a hem to further increase structural integrity of this banner type.

Backlit banners

Backlighting is what gives a promotional banner the ability to deliver its message powerfully when the lights go down. Place a traditional vinyl in front of a lightbox, however and, depending on the specific material, you’ll either block out the light so it has no effect, or the banner will appear washed out.

Backlighting requires a different banner type, one specifically designed for illumination. A backlight banner diffuses light so the image before it ‘pops’ with vibrancy and power.

Blockout banner

In many ways the direct opposite of the backlit banner, the blockout (or blackout) banner prevents light penetration. That may be vital on, for example, flagpole banners, where you’ll want the image/message to be seen from either side.

Imagine, for example, a single layer banner printed on both sides and intended for use as a flag. Bright sunlight will shine through the banner material causing the image on the rear to bleed through, confusing the image on the front.

A blockout banner sandwiches a layer of blackout material between two printed layers, so whichever side of the banner you stand and no matter how harsh the sun, you’ll always get a clear image.

Fabric banners

Polyester or canvas are the most common fabrics for banners. Polyester tends to work more effectively (and certainly more durably) when used indoors. Depending on the print method, canvas can work well outdoors – it’s the material that’s used to make sails, after all.

Lightweight polyester makes for an easily transportable, foldable, packable and washable type of banner. If you’re touring a new product around the country’s shopping malls, doing it with a polyester banner will make assembling and disassembling a lot easier. Photos look pin sharp on polyester too. Its one drawback may be durability – polyester can be prone to tearing.

That’s rarely an issue with the far more substantial canvas, which also delivers a powerfully effective medium for your print that’s low on glare and reflectance. Canvas is durable and long lasting but bear in mind that not all print methods will be appropriate for a canvas intended for outdoor use.

Also, and as you’ll know if you’ve ever had to pack away an old-fashioned tent, canvas can be heavy and bulky to transport. So it’s great for a banner that won’t need to move; less good if you’re planning on regularly re-siting it.

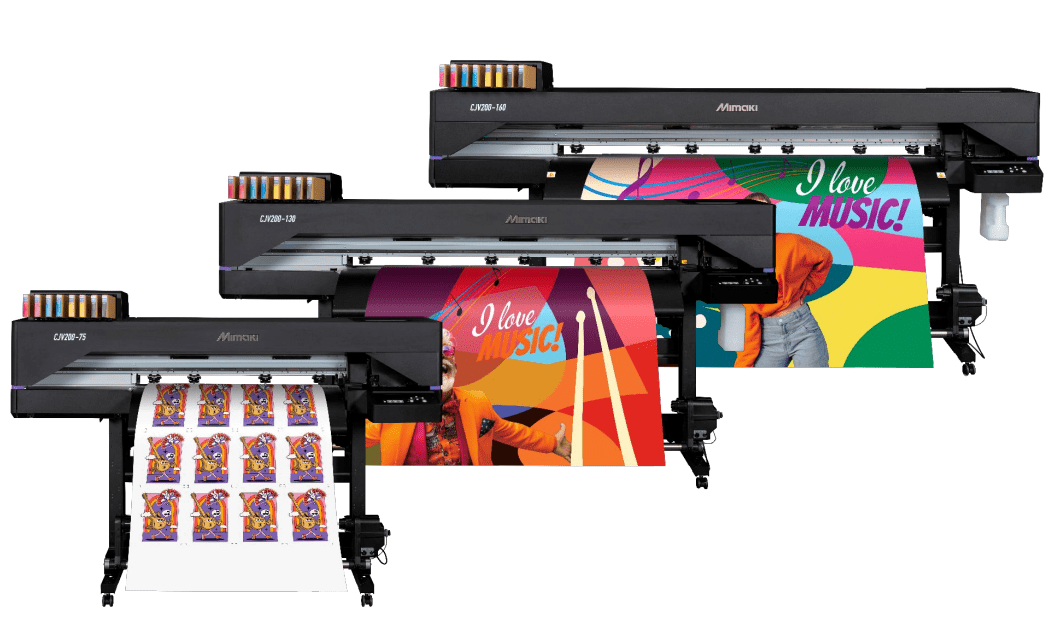

Banner options 2: Printing methods

What difference does the print method make to the banner types available to you?

Here’s the great print conundrum that everyone choosing their banner options needs to wrestle with: is it image sharpness, durability, eco-friendliness that matter most, or does your print material dictate the printing method?

Solvent

Full solvent ink (you might also see it described as ‘strong solvent’) uses a chemical-based solution containing a range of pigments and resins. It doesn’t contain water. It does contain alcohols, acetates and hydrocarbons.

Advantages of solvent printing

The advantages of solvent printing are durability and weather resistance. The solvent part of the solvent ink compound softens the material onto which the print is being applied so that the ink can penetrate. The end result is almost akin to an ink tattoo, which makes the printed image about as permanent and durable as you can achieve. Once dry, a banner type that uses a solvent-based ink will be 100% waterproof.

Solvent inks are ideal for delivering vivid image at distance. That makes them an excellent choice for large format print graphics on outdoor advertising, floor printing, textile prints (solvents are often used on stretch frames and tents used in exhibition displays) and retail graphics.

Disadvantages of solvent printing

If there’s a disadvantage to choosing solvent printing as the print method for your banner type, it’s that word ‘solvent’. Solvents can be challenging to work with because of the high volatile organic compound (COC) content, which doesn’t endear them to your average print specialist. They tend not be the environment’s best friend either.

Even once in situ, a banner printed using solvent inks may give off a lingering petrol-like odour. Outdoors, that won’t be an issue (although the potential ozone unfriendliness may be). Indoors, it can be a problem.

Eco Solvent

Take away all or most of the solvent, and is the ink that’s left still able to deliver a vivid and durable print across a range of different banner types? The simple answer is yes, and when you choose eco-friendly inks, you’ll be being much kinder to the environment and your printers.

Eco-solvents either switch out the solvent for water or use heavily refined oil extracts, which is why they’re also sometimes known as ‘mid’ or ‘low-solvent’ inks.

Advantages of eco-solvent printing

Low solvent inks are considerably kinder to the environment than solvent inks, although the ‘eco’ name might be pushing things a bit for any but genuine eco-inks which don’t use alcohol. The low odour makes banner types created using this print method capable of being used indoors as well as out.

Of greater benefit still will be the faster drying times (compared with traditional solvent inks), the bewildering colour range, the higher print speed and (generally speaking) the lower cost of printing using eco-solvents compared with solvents. This is because eco-solvents don’t require the heat that solvents need to dry – which means they can be applied to thinner, lower-cost vinyls.

Disadvantages of eco-solvent printing

Broadly speaking, the higher the eco-friendliness of the printing method used in your choice of banner options, the lower the resistance to UV and rain. That won’t be a problem for indoor banners though, and may not be an issue if you don’t need your banner to last years.

Latex

Latex inks are water based, but unlike traditional water-based inks they fuse to the print material like a solvent, which makes them waterproof and durable.

Advantages of latex printing

Latex printing is fast and odourless, which, in addition to making printers happy, means it’s easy to produce large volumes fast. Unlike solvent inks, latex inks are not hazardous to people or the environment. Colour reproduction is impressive even on large format print banner types.

Disadvantages of latex printing

Heat is a part of the latex ink print process, but not every banner type is suitable for the process, so you may have a more restricted choice of banner material options. The heat requirement can also have cost implications.

UV

By UV inks we mean ‘UV-curable’ inks, that is, inks which are dried (or cured) using UV light once the material has been printed.

Advantages of UV printing

Curing is required because the ink sits on top of the print surface rather than being absorbed by it. This makes it the natural choice for non-porous print materials. UV-cured inks are fully waterproof, so they’re ideal for outdoor applications, particularly signage, outdoor graphics and general display purposes.

Disadvantages of UV printing

Other printing methods can deliver better, sharper, more vivid print quality. The additional curing process can make this a more expensive print option.

Banner options 3: Applications

Which banner type should go where?

It may be the third element on our list but the likelihood is that this will be your first consideration. If your choice of banner material and print method are the ‘what?’ and ‘how?’ of the banner options calculation, this is the ‘where?’ and ‘who?’.

When choosing your banner options, always think in terms of the end goal. What is the message you want to get across? Where will the banner be displayed? Who will be seeing it? The answer to these questions can influence your choices.

Roller/pop-up banners

Use in close proximity to your audience and when you have limited display space to play with. Can be entirely image-led, but you may use a pop-up roller banner to deliver written information too. Designed for quick assembly/disassembly. With care, can last multiple events. Generally best kept indoors.

A popular choice for:

- Small trade shows and expos

- Sales and event promotions

- Reception areas

- Pop-up retail units

- Schools, healthcare settings, presentations, charities

Vinyl banners

Particularly well suited for outdoor applications (although fine for indoor use too when you choose latex or eco-solvent printing). Ideal for image-led banners. Waterproof.

A popular choice for:

- Expos

- Signage

- Celebrations and fetes

- Retail, school and charitable outdoor events

Mesh banners

The micro-holes in the fabric make mesh the banner type of choice for outdoor applications. The banner option most able to withstand the elements, this is the type of banner you’ll usually see displayed at height.

A popular choice for:

- Hoardings

- Building and construction wraps

- Outdoor events and staging

- Festivals

- Stadium signage

Flag banners

The motion of a flag banner is great for grabbing attention and directing traffic flow (for example, telling everyone where expo registration or the festival first aid tent are). Be aware that a flag banner is about presence and impact. If you want to convey information, choose a different banner type that won’t move quite so much.

A popular choice for:

- Festivals

- Exhibitions and events

- Retail spaces (indoor and out)

Banner options 4: Finishing & Hemming

The finishing touches to ensure your banner can do its job.

Your decision about finishing and hemming options goes hand in hand with the fixings you choose (see below). These are the most common options:

Grommets

If you’re going to pass something through the edges of your banner to secure it in place (rope, zip ties, bungee cords etc) you’ll need to ensure there are a) holes in your banner through which those fasteners can pass and b) those holes are reinforced so the fixing doesn’t tear into the banner material when the wind starts blowing. That’s the role of grommets (or ‘eyelets’).

Wind slits or flaps

Not essential for all banner types, but valuable for solid vinyls which wouldn’t otherwise allow the wind to pass through. Adding wind slits can help protect your banner and ensure it remains clear and legible rather than billowing and distorting in strong winds.

Banner hemming

Not essential for all banner options. You won’t, for example, necessarily need a hem when the banner is going to be secured in a box frame or velcroed to a fabric sleeve, but you will need to add a hem when the banner will be suspended or secured using ropes, bungees or ties. The hem adds strength and ensures that neither the weather nor the weight of the banner causes rips or distortion.

Different banner types may use different types of hem fixings, with options including glue, stitching and heat welding.

Sail track edging

A rigid banner finish that can work well on large outdoor installations such as billboards.

Banner options 5: Fixings

The banner is ready to deliver its impact. Now, you just need to ensure that once it’s fixed in place, it will stay there.

Not every type of banner needs a fixing method. Choose a roller banner, for example, and the frame that will keep it standing proud is an integral part of the product. But for most banner types, once the print is dry and the banner is ready to go, you’ll need to find an appropriate way of fixing it in place.

Zip ties

It may be the most low-tech banner fixing option on this list, but simple zip ties can be perfectly effective at securing mesh and vinyl banners to fences and railings. Capable of doing the job in outdoor environments, they’re also quick to fix in place and easy to snip off again when you no longer need them. Just ensure your banner has eyelets to give the ties something to slip through.

Velcro

Not an outdoor option, but Velcro can be effective for large format indoor print banners. Frequently used to secure print to freestanding exhibition display stands.

Bungee cords

Great for use outdoors as the natural elasticity of the cords helps take some of the stress forces off the banner and the fixing surface. Can help keep your banner stay in shape for longer in windy environments.

Nylon rope

Suitable for banner types with pole pockets or grommets. Weave the rope through the pockets (or in and out through the grommets) to ensure a strong fix that doesn’t cause your banner to bunch up. As an alternative for pole pockets, consider using a rod or dowel.

Flag banner fixings

Of all the different banner types, none has quite so many fixing options as the flag banner. There’s the simple cross base or flat base (for indoor applications without the potential trip hazard of a cross base). Spikes or augers are ideal for soft ground, while marquee mounts minimise floor clutter by enabling your flag banner to piggyback on the marquee frame.

To discuss your application and the different banner types that may be suitable for it, talk to us.